Menu

Filter Bags Manufacturer & Supplier

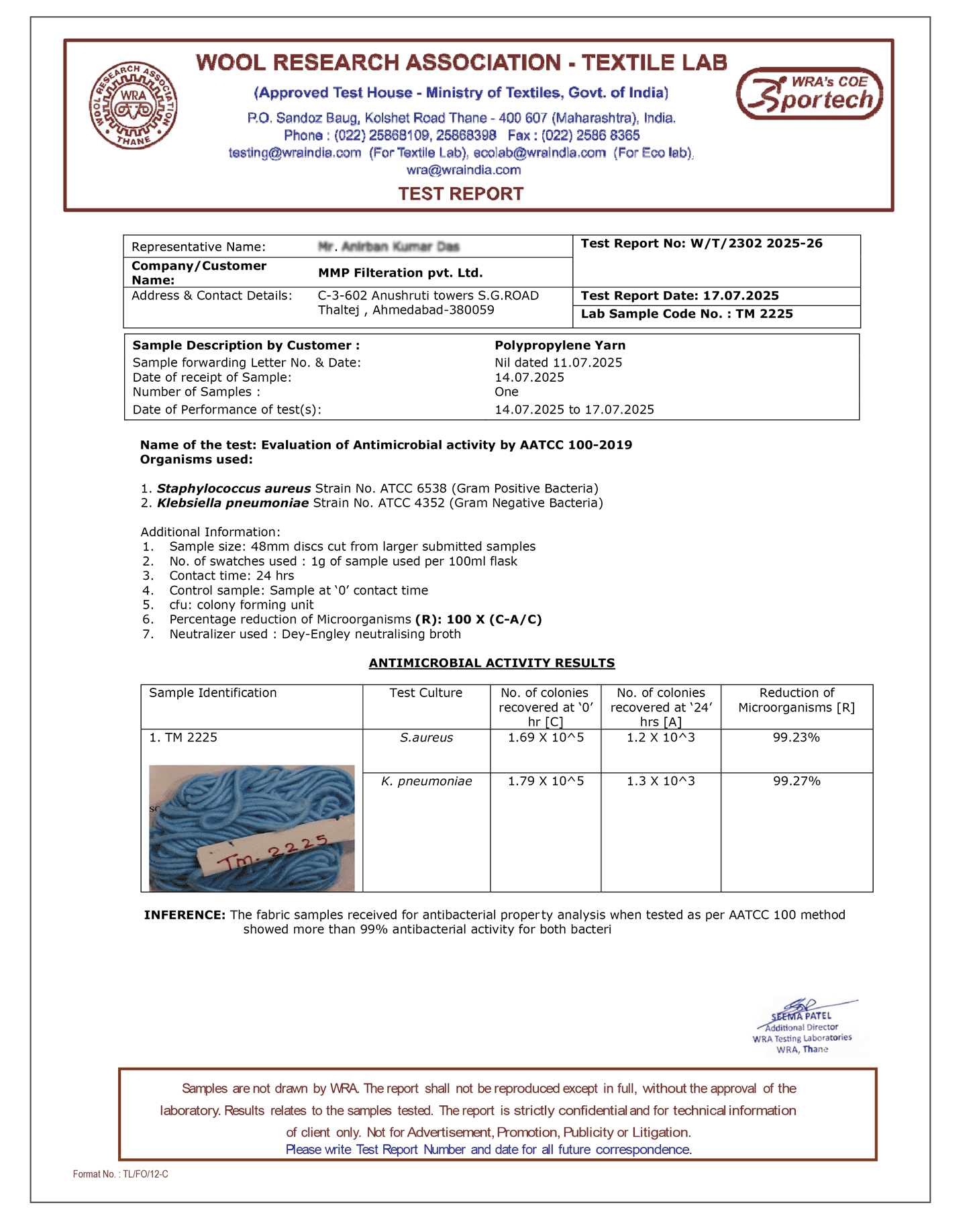

MMP engineers top-quality, high-volume Industrial Filter Bags that provide performance, durability, and reliability in the toughest of operating Conditions. mmp-manufactured Bag Filters are utilized within numerous different industries as an effective and economical method for removing impurities from air. All mmp-manufactured Filter Bags are available in, but not limited to, the following materials: Polyester Felt, Polypropylene Felt, Glass Fibre, Polyimide, etc. Filters Bags utilizing these materials are sold and distributed worldwide, including locations such as the USA, UK, UAE, Australia, as well as many other countries.

We manufacture filtration bags that are designed specifically for bag filtration applications where there is a high dust or high load of dust in an industrial setting, including a few examples such as the cement industry, steel factories, foundries, and mines. Our dust collector systems use the most advanced non-woven and woven filter fabrics to provide maximum filtration capability in the most demanding conditions. All of our bag filters are designed for operation at extreme temperatures with high forced and unforced air-to-cloth ratios, while gathering the smallest of airborne particulate matter possible for cleaner work places, less environmental pollutants, and compliance with government regulations in the workplace. The filter construction allows us to have optimum filtration performance and minimal pressure drop, which means longer runtimes and better performance. If you're in the cement industry and dealing with clinker dust or if you're in the metals industry and are dealing with fine steel dusts, our polypropylene filter bags and other materials can withstand the toughest industrial environments.

| Technical Name | Filter Bags |

| Fabric |

|

| Coating on Fabric |

|

| Fitment |

|

| Joint |

|

| ID & OD |

|

| Length |

|

Developed for extreme and severe industrial environments like steel, cement, mining, or foundries, these bags catch fine and coarse particles efficiently while fighting the high heat and Grit.

An advanced upgrade to traditional bags, pleated designs offer a larger surface area. That means more dirt-holding capacity, fewer changeouts, and better airflow, all while saving space.

Perfect for pharma, food, woodworking, and powder coating facilities.

At mmp filtrations, our Bag Filters are designed to do more than just capture dust or particles; they're built to keep your operations running clean, smooth, and uninterrupted. Every element and component is crafted with real-world performance keeping in mind, providing reliability across demanding industrial environments.

Effective Filtration

Filter bags by mmp are created and built to provide consistent, efficient filtration across a wide range of particulates, from fine dust to larger particles. They keep the same level of performance as they provide for air filtration over an extended period of time, helping you maintain compliance with air quality regulations and protecting downstream equipment.

Durability

Every stitch of the construction of our filter bags is manufactured to be very strong, and we provide two construction styles for customer choice. Options for heat sealing and/or double-stitched construction provide resistance to tearing and stress/pressure, even when they are working under a high volume of debris or exposed to extreme heat. You can depend on the durability of our bag filters from shift to shift.

Wide Range of Material Options

Every industry faces distinct filtration challenges, so we manufacture Filter Bags in many different media types, such as polyester, polypropylene, aramid, PTFE, and more, to address those challenges. We can also offer customized solutions for other unique needs, such as FDA-compliant food-grade bag filters or filter media materials with chemical resistance suitable for use in very harsh conditions.

Low Energy Operation

Our Filter Bags are designed not only for performance but also for efficiency. They maintain optimal airflow or fluid flow while requiring less energy to operate your dust collection or air filtration systems, ultimately lowering your operational costs and energy bills.

Fast, Hassle-Free Installation

Time is money, and we respect both. That’s why our bag filters are designed for quick and easy installation. With standard and custom collar designs available, changeouts are faster, reducing system downtime and keeping your production line moving.

Custom Fit Capability

No two filtration systems are alike, which is why we offer custom-made Filter Bags to perfectly fit your existing housing units and equipment. From sizing and stitching to media selection and finishing, we ensure a precise fit that enhances filtration efficiency and ease of use.

Whether it’s dust collection in a cement plant or fine filtration in a pharmaceutical unit, our bag filters are engineered to deliver dependable, long-lasting results no matter the challenge.

Every industry faces unique filtration challenges. At mmp filtrations, we recognize that a one-size-fits-all solution doesn’t work, so we’ve engineered specialized Filter Bags designed to meet the exact demands of your process, environment, and compliance standards. Here's how we serve different sectors with precision:

Filter Bags for the Cement Industry

Dust is relentless in cement manufacturing. Our Bag Filters for Cement Plants are crafted to handle extremely high temperatures, abrasive dust particles, and heavy particulate loading. Whether it’s in kilns, crushers, mills, or bagging stations, our dust collector bags offer maximum efficiency with long operational life, reducing emissions and ensuring smoother plant operations.

Filter Bags for the Pharmaceutical Industry

Cleanroom standards and reducing the risk of contamination are important components of pharmaceutical manufacturing. To help achieve these goals, we offer Pharmaceutical Grade Bag Filters manufactured with Low-Shedding FDA Compliant Materials that provide Exceptional Fine Dust Retention. Pharmaceutical Grade Filter Number Bags will support Sterile Processing Lines, Air Filtration, and Product Safety, all while meeting cGMP and Regulatory requirements with Confidence.

Filter Bags for the Chemical Industry

Chemical plants need filtration solutions that can stand up to corrosive gases, aggressive solvents, and reactive powders. Our Chemical Industry Filter Bags are constructed from chemically resistant materials like PTFE and aramid blends. Designed to handle volatile environments, they deliver reliability and safety in reactors, mixers, and powder handling systems.

Filter Bags for the Water Treatment Industry

Filter bags for water treatment are used in municipal treatment plants and industrial wastewater unit applications, but keep catching suspended solids, organic material, and sludge. Bag Filters for water treatment can be used in both prefiltration and polishing stages, as well as in continuous flow operation, along with protecting downstream equipment to provide clean water and environmental compliance.

Filter Bags for the Textile Industry

Textile manufacturing facilities release airborne fibers, dust, and lint, which can have an impact on the air quality as well as the machinery. Our filter bags for the textile sector control the emission of contaminants during spinning/weaving/dyeing/finishing processes. The bag filters are made using heavy-duty and static-free materials, allowing for a continuous workflow and ultimately creating a cleaner atmosphere in the facility.

Filter Bags for the Dairy Industry

Airborne particles can become a significant hygienic risk when the dry processing areas of Dairy Manufacturing Facilities, such as Milk Powder, Cheese Powder & Lactose, are in operation. To preserve hygiene/safety, Dairy Industry Bag Filters are manufactured using FDA-approved food contact materials. We offer filters for Dust Collection, meeting stringent sanitary standards.

Filter Bags for the Oil & Gas Industry

Oil and gas refineries and oil and gas upstream exploration sites encounter complex hydrocarbons and abrasive particulate matter at very high temperatures. With these environments, we have developed a wide range of Filter Bags for Oil and Gas that provide a high degree of thermal resistance, chemical compatibility, and particulate filtration. This allows for the continued protection of sensitive equipment while maximizing operational uptime.

Filter Bags for the Power Plant Industry

Coal and biomass power plants produce particulate matter, including fine ash, fly ash, and very high temperature gases, which require tough filtering capabilities. Our Power Plant Bag Filters are specifically designed to trap fine particulate matter while withstanding hot and corrosive flue gas temperatures to comply with emission regulations and to enhance the operation of heat recovery systems in power plants.